Vacuum formed is a versatile manufacturing process widely used across industries for creating a myriad of products with precision, efficiency, and cost-effectiveness. This method involves heating a thermoplastic sheet and then stretching it over a mold, using a vacuum to form the desired shape. The resultant product can vary in complexity, size, and thickness, making vacuum forming a popular choice for a diverse range of applications. In this article, we will explore the significance, process, applications, and advantages of vacuum forming.

Significance of Vacuum Forming

Versatile Manufacturing Technique:

Vacuum forming allows the creation of complex shapes and parts, catering to diverse industry needs.

Cost-Effective Production:

This process offers cost-efficient manufacturing of prototypes, custom parts, and large-scale productions.

The Vacuum Forming Process

Heating:

A thermoplastic sheet is heated until it becomes pliable and ready for molding.

Forming:

The softened sheet is stretched over a mold and held in place while a vacuum draws it tightly against the mold’s surface, creating the desired shape.

Cooling and Trimming:

Once formed, the product is cooled and then trimmed to achieve the final shape.

Applications and Versatility

Packaging:

Vacuum forming is extensively used in creating packaging for consumer goods, electronics, and food products.

Automotive Industry:

It’s employed in manufacturing vehicle components, such as dashboards, interior panels, and protective covers.

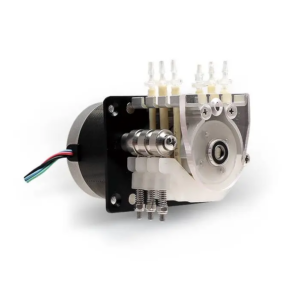

Medical Equipment:

This technique produces enclosures and components for medical devices due to its precision and customization capabilities.

Advantages and Considerations

Customization:

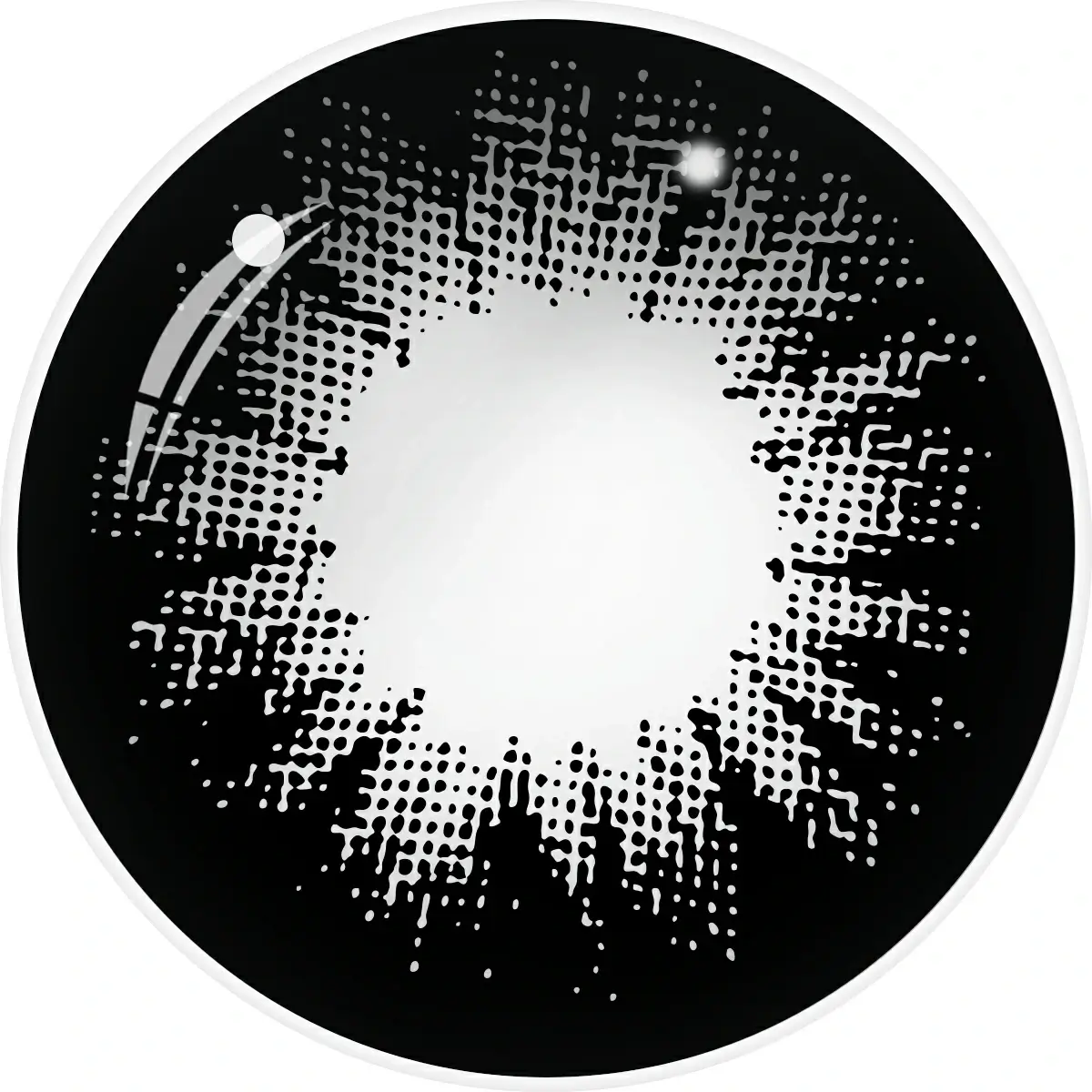

Vacuum forming allows for customization in design, color, and texture, catering to specific product requirements.

Rapid Prototyping:

It enables swift prototyping and quick production runs, facilitating efficient product development cycles.

Material Selection:

A variety of thermoplastic materials can be utilized, offering flexibility in choosing materials based on application needs.

Vacuum formed stands as a pivotal manufacturing process, offering versatility, cost-effectiveness, and flexibility in producing a wide array of products across diverse industries. Its ability to create intricate shapes, swift prototyping, and material flexibility makes it a favored choice in various applications. When considering manufacturing methods, the vacuum forming process stands out for its adaptability, efficiency, and cost-effectiveness in producing customized and intricate parts. By leveraging vacuum forming, industries can streamline production, create custom products, and swiftly bring innovative ideas to life. Remember, the significance of vacuum formed lies in its versatility, efficiency, and adaptability, catering to a wide spectrum of industrial needs with precision and cost-effectiveness.