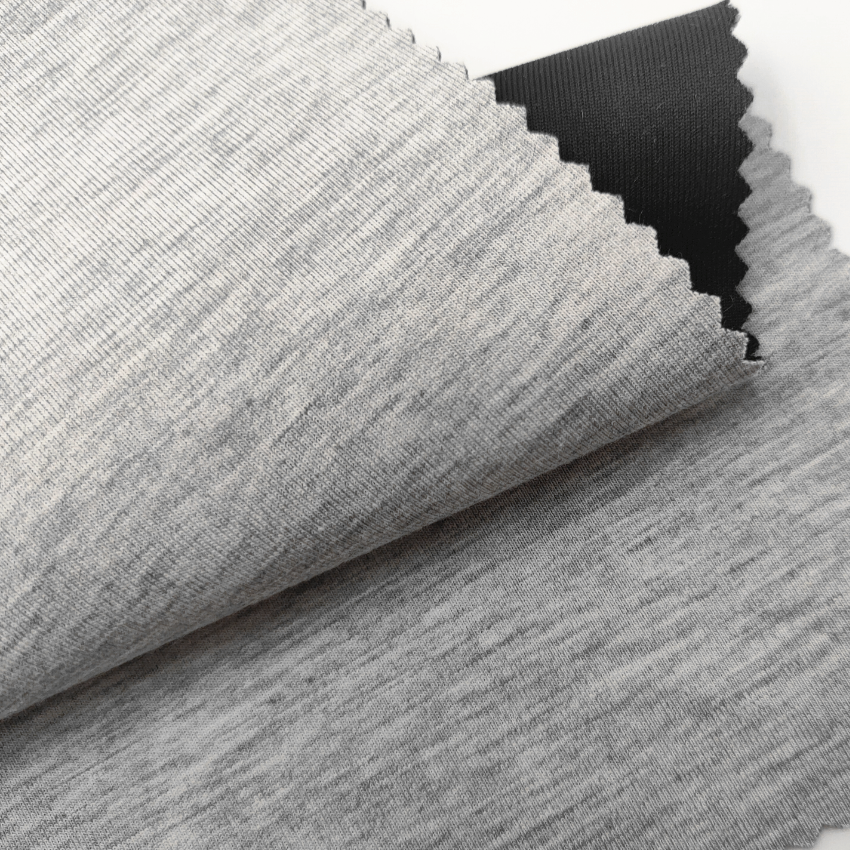

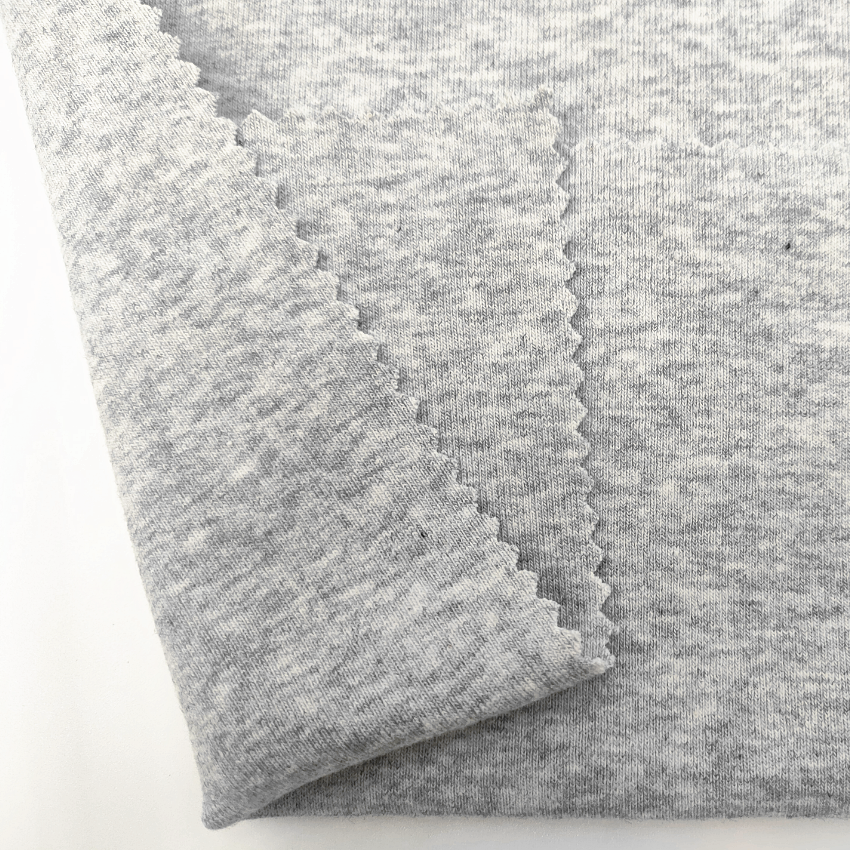

The impact of Spacer Fabric Interlock Fabric production on biodiversity depends on various factors such as the specific materials used, production processes, and waste management practices. Spacer Fabric and Interlock Fabric are specialized textiles often used for applications like sportswear, activewear, and technical clothing.

The environmental impact, including effects on biodiversity, can be influenced by several aspects:

- Raw Material Selection:

- The choice of raw materials, such as the fibers used in Spacer Fabric Interlock Fabric, can impact biodiversity. For example, if the fabric incorporates organic or sustainably sourced fibers, it may have a lower impact compared to conventional materials.

- Synthetic vs. Natural Fibers:

- If Spacer Fabric Interlock Fabric is made from synthetic fibers, such as polyester or nylon, the production process may involve petrochemicals and contribute to environmental issues. On the other hand, if natural fibers like organic cotton are used, it might have a lower ecological footprint.

- Dyeing and Finishing Processes:

- The dyeing and finishing processes during fabric production can impact water quality and biodiversity if chemicals are not managed properly. Efforts to use eco-friendly dyes and reduce water consumption contribute to more sustainable practices.

- Chemical Management:

- The use of chemicals, including detergents and finishing agents, can affect ecosystems if not properly managed. Best practices include the adoption of closed-loop systems, proper wastewater treatment, and adherence to environmental regulations.

- Energy Consumption:

- The energy source for manufacturing processes plays a role in the environmental impact. If Spacer Fabric Interlock Fabric is produced using renewable energy sources, it can mitigate its carbon footprint. China Spacer Fabric Interlock Fabric suppliers High energy consumption, especially from non-renewable sources, can contribute to climate change, indirectly affecting biodiversity.

- Waste Management:

- Proper disposal or recycling of waste generated during the production of Spacer Fabric Interlock Fabric is crucial. Inadequate waste management can lead to pollution and negatively impact biodiversity, especially if harmful substances leach into the environment.

- Certifications and Standards:

- Compliance with environmental certifications and standards, such as OEKO-TEX or bluesign®, indicates a commitment to sustainable and environmentally friendly practices. These certifications often consider factors like chemical use, water management, and worker conditions.

- Supply Chain Transparency:

- Transparent supply chains allow for better accountability and monitoring of the environmental and social practices throughout the production process. Companies that prioritize transparency often adopt more sustainable practices.

- Biodiversity Conservation Efforts:

- Some textile manufacturers may implement biodiversity conservation efforts, such as protecting natural habitats, supporting reforestation projects, or engaging in initiatives that contribute positively to local ecosystems.

- Innovation in Sustainable Practices:

- Ongoing innovation in sustainable technologies and practices can lead to reduced environmental impact. For example, advancements in waterless dyeing or closed-loop production systems can contribute to more sustainable Spacer Fabric Interlock Fabric production.

It’s essential for manufacturers in the textile industry to adopt a holistic approach, considering the entire lifecycle of their products and implementing sustainable practices to minimize negative impacts on biodiversity and the environment. Consumers can also play a role by choosing products from companies committed to ethical and environmentally responsible practices.