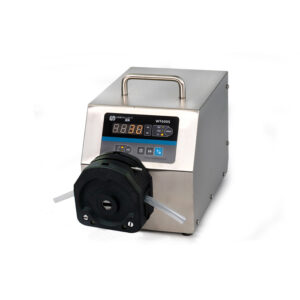

A variable frequency peristaltic pump from China operates based on the principles of peristalsis, which involve the compression and relaxation of a flexible tube to move fluid through it.

Here’s how it works:

- Tube Configuration: The pump consists of a flexible tube made of materials like silicone or thermoplastic elastomers. The tube is positioned in a circular pump head or rotor assembly.

- Rotor Assembly: The rotor assembly comprises a series of rollers or shoes that rotate continuously in a circular motion. These rollers or shoes press against the flexible tube, creating a squeezing or compressing action.

- Fluid Flow: As the rotor rotates, the rollers or shoes sequentially compress and release different sections of the flexible tube. This action propels the fluid inside the tube in a forward direction.

- Variable Frequency Drive: The variable frequency peristaltic pump is equipped with a variable frequency drive (VFD). The VFD controls the speed and rotational direction of the rotor assembly.

- Speed Control: By adjusting the frequency and voltage supplied to the motor, the VFD regulates the rotational speed of the rotor assembly. Higher frequencies result in faster rotation, while lower frequencies reduce the speed.

- Flow Rate Control: The speed of the rotor assembly directly influences the flow rate of the fluid. Increasing the speed increases the flow rate, while decreasing the speed lowers it. The VFD enables precise control of the pump’s flow rate by adjusting the rotational speed accordingly.

- Reversing Function: Some variable frequency peristaltic pumps have a reversing function, allowing the rotor assembly to change its rotational direction. This feature is useful for specific applications that require bidirectional fluid flow or for clearing any blockages or air pockets in the tubing.

- Control Interface: The pump may have a control interface that allows users to set and adjust parameters such as speed, flow rate, and direction. This interface can be a digital display panel or a computer-based control system, depending on the pump’s design and capabilities.

- Safety Features: Variable frequency peristaltic pumps typically include safety features such as motor overload protection, overcurrent protection, and emergency stop functions to ensure safe operation and prevent damage to the pump or system.

By using the variable frequency drive to control the speed and direction of the rotor assembly, the China variable frequency peristaltic pump offers precise and adjustable fluid flow rates. This makes it suitable for applications where accurate dosing, metering, China variable speed peristaltic pump or continuous flow control is required, such as in medical, laboratory, industrial, or research settings.

Here are some additional details about variable frequency peristaltic pumps from China:

- Motor Types: Variable frequency peristaltic pumps can be equipped with different types of motors, such as stepper motors or brushless DC motors. These motors provide smooth and precise control over the rotational speed and offer excellent repeatability.

- Tube Selection: China variable frequency peristaltic pumps often support a wide range of tube sizes and materials. This flexibility allows users to choose the most appropriate tubing based on factors like fluid compatibility, flow rate requirements, and application-specific needs.

- Control Modes: Variable frequency peristaltic pumps may offer various control modes to suit different applications. For example, they can operate in fixed speed mode, where the rotational speed remains constant, or in variable speed mode, where the speed can be adjusted based on flow rate demands.

- Programmable Operation: Some advanced variable frequency peristaltic pumps have programmable operation capabilities. Users can define and store multiple pumping programs with specific speed profiles, intervals, and flow rates. This feature enables automation and simplifies repetitive tasks.

- Communication and Integration: Certain variable frequency peristaltic pumps are designed to integrate with external systems or equipment. They may include communication interfaces such as RS485, Ethernet, or Modbus, allowing for remote control, data logging, and integration into larger automated systems.

- Multi-Channel Pumping: China variable frequency peristaltic pumps can be available in single-channel or multi-channel configurations. Multi-channel pumps have multiple pump heads or rotor assemblies, enabling simultaneous pumping of different fluids or multiple channels of the same fluid.

- Calibration and Calibration Memory: High-quality variable frequency peristaltic pumps often feature calibration options to ensure accurate and precise fluid delivery. They may allow users to calibrate the pump for specific tubing sizes or flow rates, and some pumps even have calibration memory to store calibration data for future use.

- Maintenance and Tube Replacement: The design of variable frequency peristaltic pumps often simplifies maintenance and tube replacement. They may have quick-release mechanisms or easy-access pump heads that facilitate tube changes, minimizing downtime and ensuring efficient operation.

- Application Range: Variable frequency peristaltic pumps find applications in various industries and fields, including pharmaceuticals, biotechnology, food and beverage, chemical processing, environmental analysis, and research laboratories. They are well-suited for tasks such as dosing, sampling, filling, cell culture, chromatography, and more.

- Customization and OEM Solutions: Chinese manufacturers of variable frequency peristaltic pumps often offer customization options and OEM (Original Equipment Manufacturer) solutions. This allows users to tailor the pump design, specifications, and features to meet specific application requirements or integrate the pump into specialized equipment or systems.

When considering a variable frequency peristaltic pump from China, it is important to review the manufacturer’s reputation, quality control processes, and customer support services. Additionally, comparing specifications, features, and pricing across different models and brands can help you select the most suitable pump for your specific needs.