Peristaltic pumps, known for their precision and reliability in fluid handling, boast a level of accuracy essential for various industries. This article aims to delve into the intricacies of peristaltic pump accuracy and its significance in delivering precise fluid transfer across diverse applications.

The Essence of Accuracy in Peristaltic Pumps

Defined by Design:

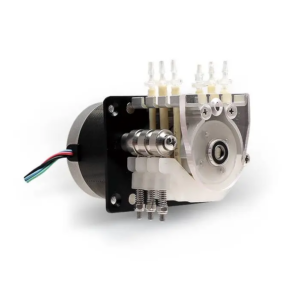

- Mechanism of Action: Peristaltic pumps employ rollers or shoes that compress flexible tubing, generating a controlled flow by squeezing and releasing the fluid, ensuring precise and consistent dosing.

- Minimal Contamination: Their design minimizes the risk of fluid contact with pump components, offering accurate transfer without the risk of contamination.

Factors Influencing Accuracy

Tube Selection and Quality:

- Material Considerations: The choice of tubing material significantly impacts accuracy, with variations in material elasticity, thickness, and compatibility affecting the pump’s performance.

- Consistency and Quality: Maintaining tube integrity and quality ensures consistent flow rates, vital for achieving accuracy in fluid transfer.

Pump Design and Calibration:

- Precision Engineering: The pump’s design, rotor speed, and tubing diameter play pivotal roles in determining accuracy. Calibration of these components ensures reliable and consistent performance.

- Flow Rate Control: Modern peristaltic pumps feature advanced control systems that enable precise adjustments in flow rates, enhancing accuracy for specific applications.

Applications and Importance

Laboratory and Pharmaceutical Settings:

- Precise Dosing: Peristaltic pumps provide accurate fluid delivery crucial for laboratories, pharmaceutical manufacturing, and research, ensuring precise dosing and formulations.

- Sensitive Experiments: Their accuracy is vital in delicate experiments where the slightest deviation can impact results, such as chromatography or bioreactor operations.

Industrial and Biotechnological Applications:

- Controlled Processing: Industries rely on peristaltic pumps for accurate chemical dosing, wastewater treatment, food and beverage processing, and biotechnological applications.

- Critical Processes: Accuracy is paramount in critical processes where precise chemical ratios or volumes are essential for successful outcomes.

Ensuring and Maintaining Accuracy

Regular Maintenance:

- Tubing Replacement: Regularly replacing tubing prevents wear and tear, maintaining consistent flow rates and accuracy.

- Calibration Checks: Periodic calibration and validation of pump components are necessary to uphold accuracy standards.

Peristaltic pump accuracy stands as a cornerstone in various industries, ensuring precise fluid transfer for critical processes. By virtue of their design, material selection, and meticulous calibration, these pumps deliver reliable and accurate performance, making them indispensable in laboratories, pharmaceuticals, industries, and research settings. Upholding and maintaining accuracy through proper calibration, quality tubing, and regular maintenance are paramount to ensure optimal performance and precision in fluid handling processes.