Choosing the right filter press plate for your application can depend on a variety of factors, including the type of material being filtered, the desired filtration rate, and the specific requirements of the process.

Here are some key factors to consider when selecting a filter press plate:

Material: The material being filtered will play a big role in determining the type of plate needed. For example, a highly corrosive material may require a plate made from a more durable material such as stainless steel or titanium, while a less corrosive material may be suitable for a plate made from polypropylene.

Filtration rate: The desired filtration rate will impact the design of the plate. If a high filtration rate is needed, a plate with larger channels or grooves may be needed to allow the liquid to flow more quickly.

Cake release: The ability of the filter cake to release from the plate can impact the efficiency of the filtration process. Some plates may have a special coating or texture to aid in cake release.

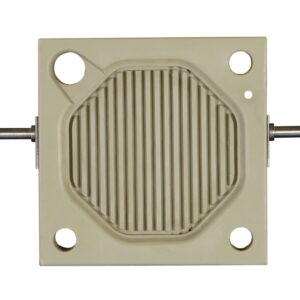

Plate size and configuration: The size and configuration of the plate will depend on the size of the filter press and the specific requirements of the process. For example, plates may be round, square, or custom-shaped, and may be designed to stack in different configurations depending on the needs of the application.

Maintenance and cleaning: Some plates may be easier to clean or maintain than others, which can impact the overall efficiency and cost-effectiveness of the filtration process.

Overall, selecting the right filter press plate for your application will require careful consideration of the specific needs and requirements of the process. Consulting with a filtration expert or supplier can be helpful in determining the best plate for your application.

How can I determine the right plate size and configuration for my filter press?

Selecting the right plate size and configuration for your filter press will depend on a variety of factors, including the type of material being filtered, the desired filtration rate, and the specific requirements of the process.

Here are some key factors to consider when determining the right plate size and configuration:

Filter press capacity: The size of the filter press will impact the size and configuration of the plates. A filter press with a higher capacity will require larger plates or more plates to achieve the desired filtration rate.

Material being filtered: The type of material being filtered will impact the size and configuration of the plates. For example, a material with a high solids content may require larger plates or a different plate configuration to achieve optimal filtration.

Filtration rate: The desired filtration rate will impact the size and configuration of the plates. filter press plates A higher filtration rate may require larger plates or a different plate configuration to allow for faster flow of the liquid being filtered.

Available space: The available space in the filtration area will impact the size and configuration of the plates. If space is limited, a smaller plate size or a different plate configuration may be needed.

Maintenance and cleaning: The size and configuration of the plates can impact the ease of maintenance and cleaning. Some plate configurations may be more difficult to clean or maintain than others, which can impact the overall efficiency and cost-effectiveness of the filtration process.

Overall, selecting the right plate size and configuration for your filter press will require careful consideration of the specific needs and requirements of the process. Consulting with a filtration expert or supplier can be helpful in determining the best plate size and configuration for your application.